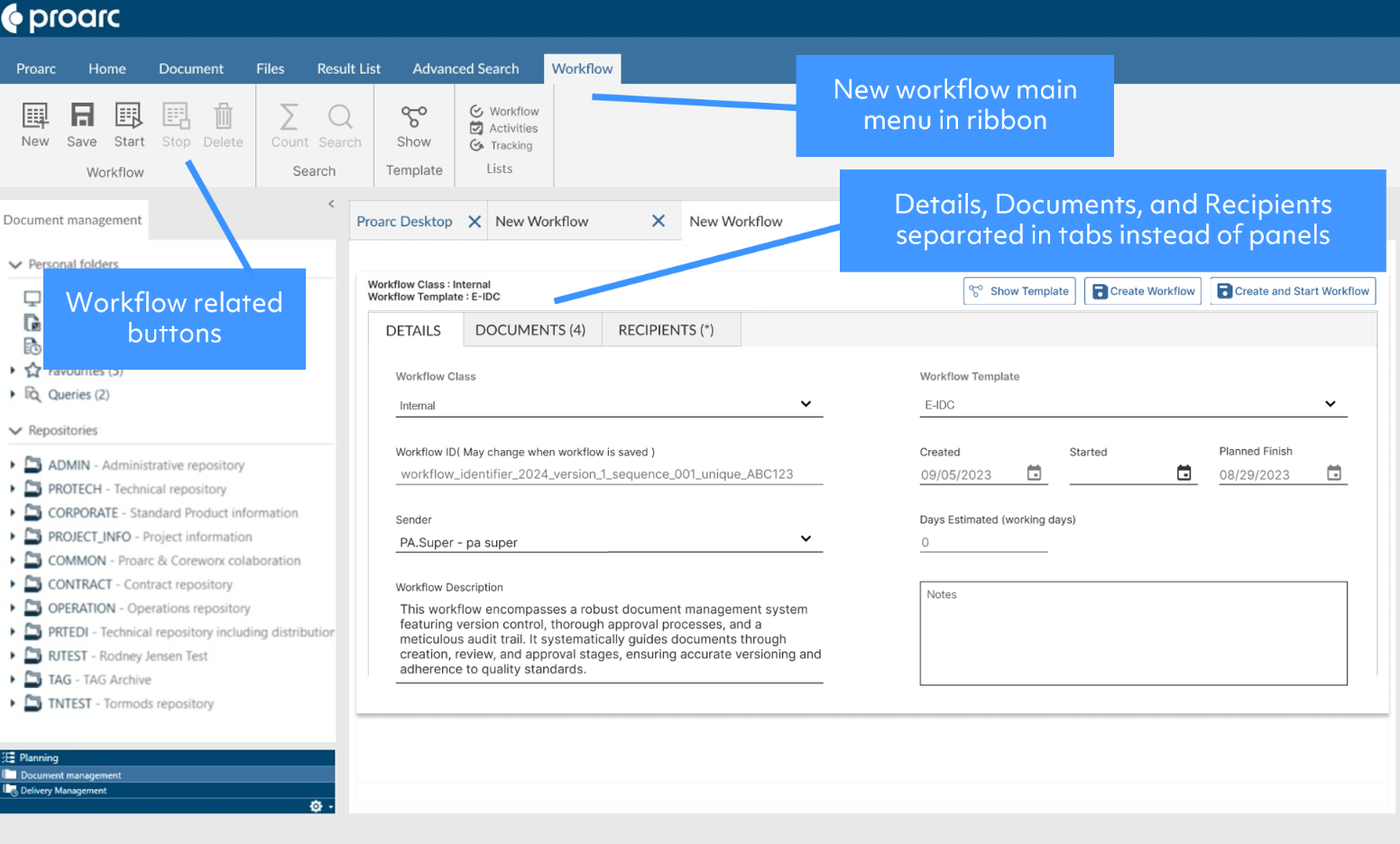

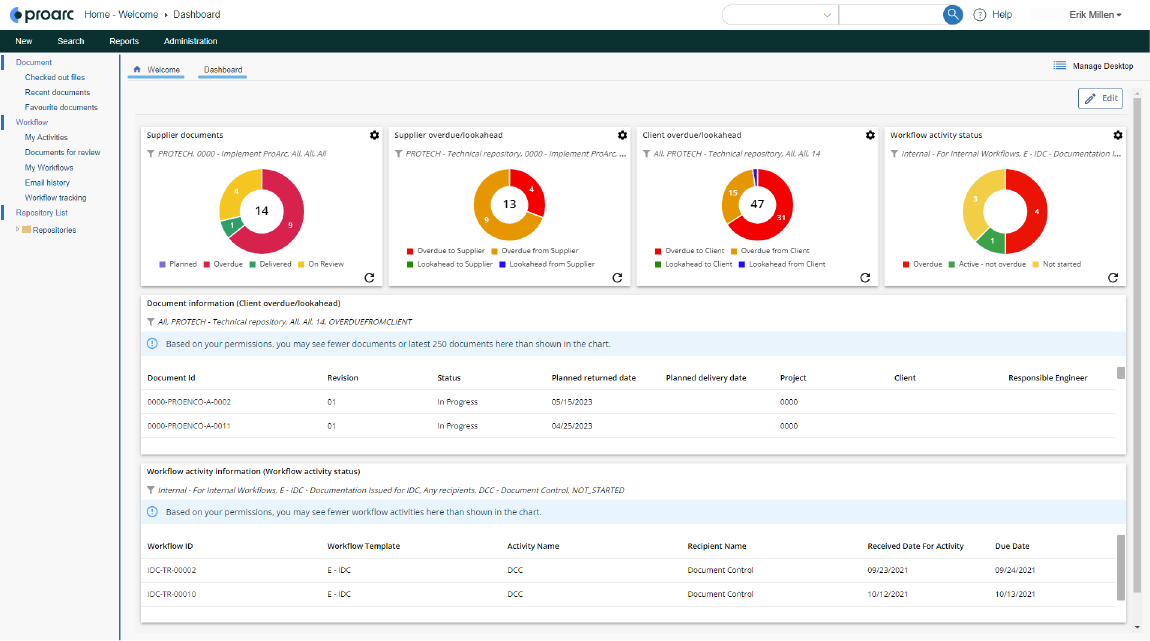

Document Management

Engineering document management

system (EDMS) and document control software

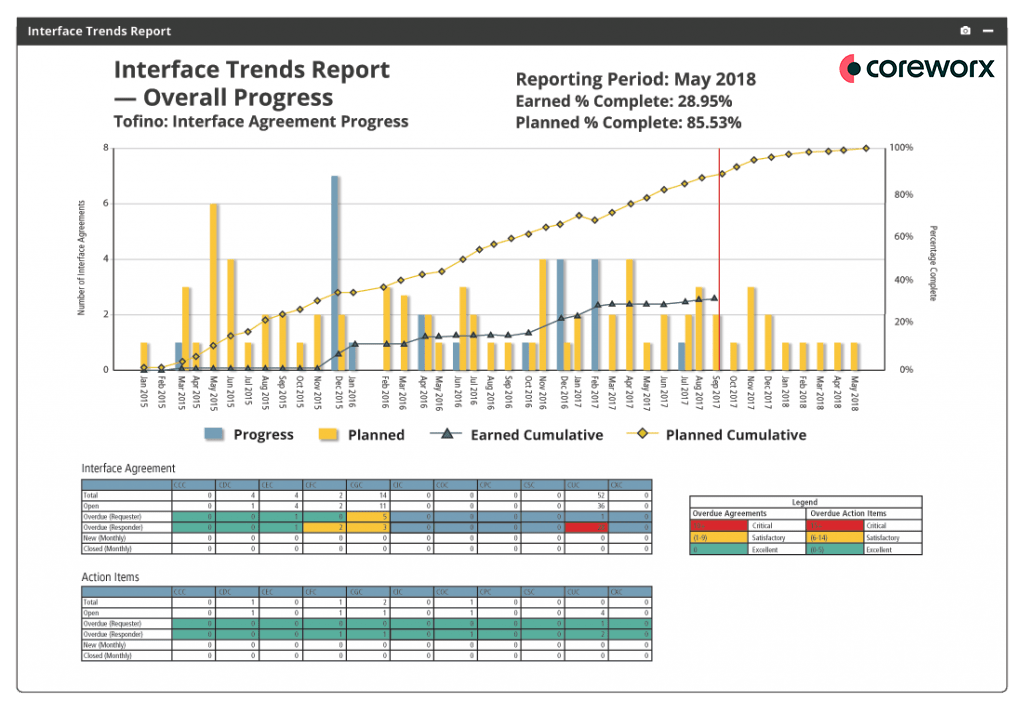

Project Controls

Project control and cost management software that provides complete control of project costs and drives better performance

Project Controls & Cost Management Software

Ascertra systems give you reliable information

to design, deliver and operate complex assets

with added insight.

© 2024 Ascertra | Privacy Policy | Norwegian Transparency Act