Information Management Software

for Projects & Asset Operations

Information is the center point of successful capital projects and asset operations.

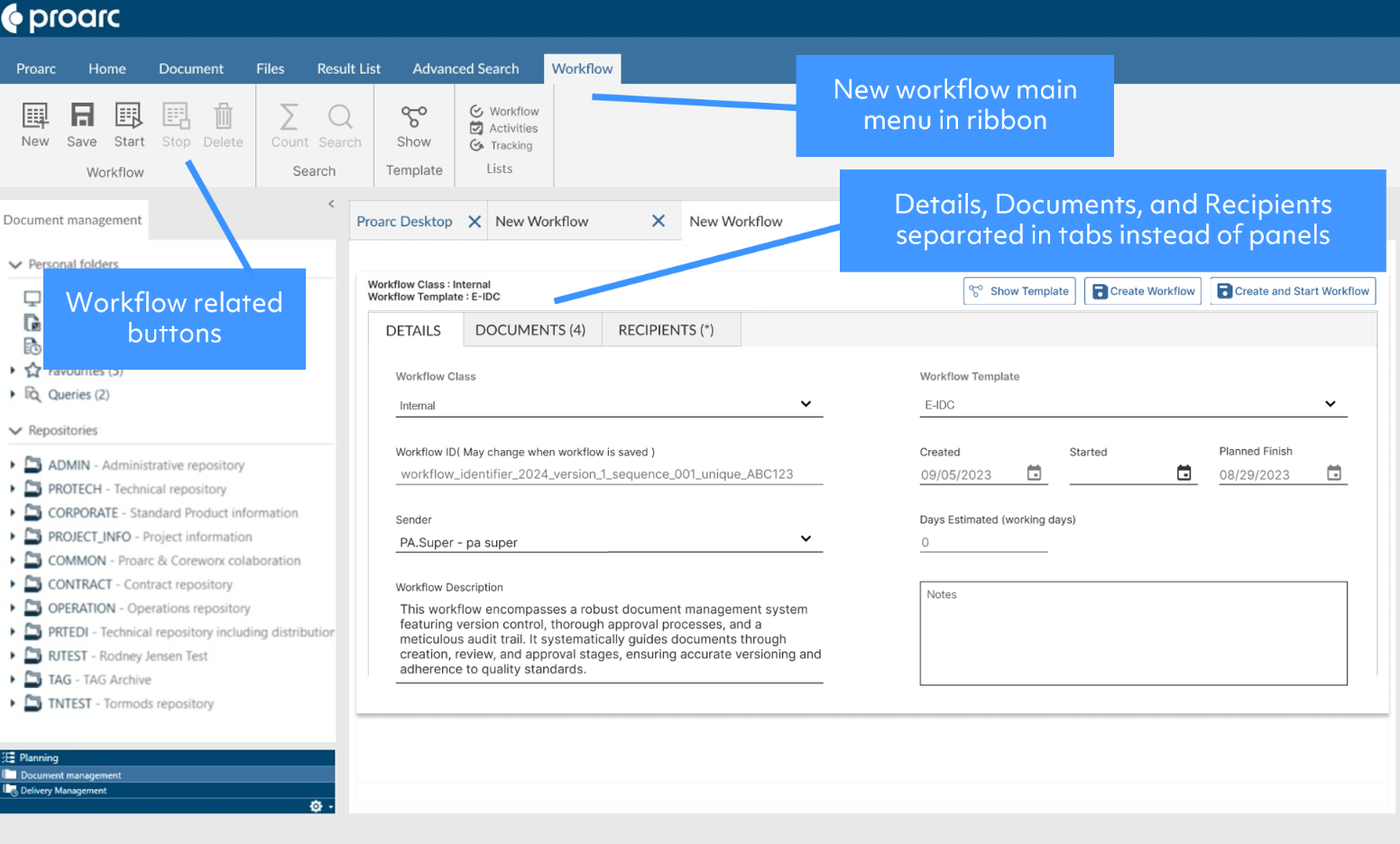

Our purpose-built document control, interface management, and project controls software solutions

provide teams with information certainty at every stage when engineering,

constructing, and operating complex assets.

Information Management Powers Progress

Securely manage volumes of business-critical documents

Reduce costly errors caused by incorrect information

Empower every team member with the right information

Ensure compliance to industry information management practices

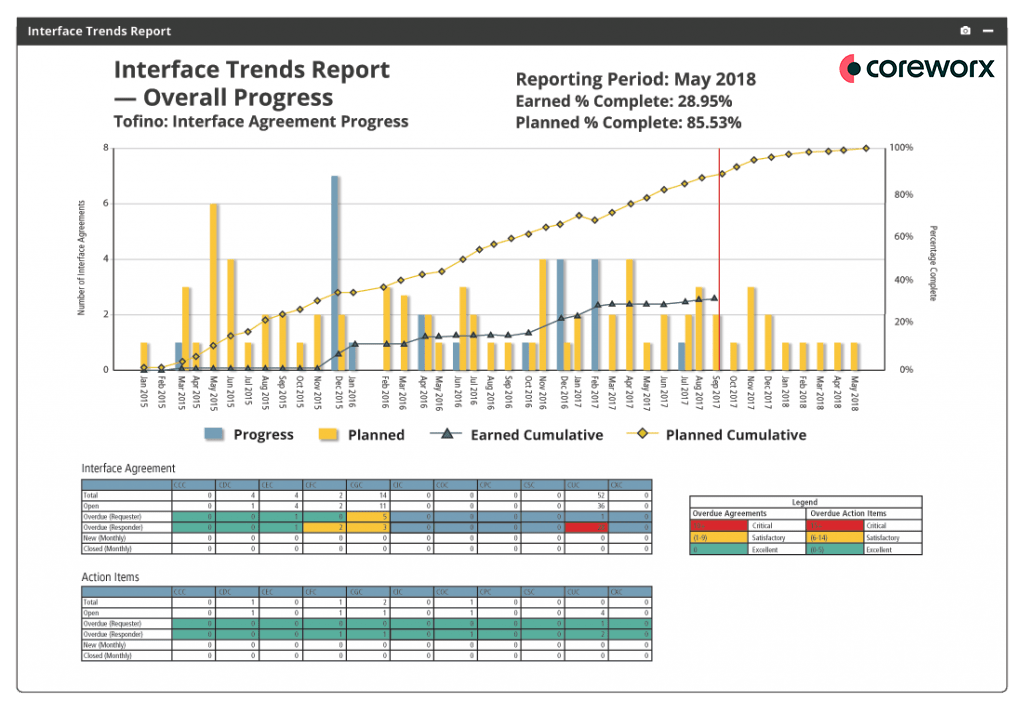

Identify and mitigate risk with increased visibility to potential issues

Reduce claims and resolve disputes with complete audit history

Improve team performance with proven industry solutions that have been helping teams power their progress for more than 40 years

registered users